The Evolution of Refineries: Navigating the Shift from Crude to Chemicals

Refineries worldwide are undergoing a pivotal transformation as the industry moves from traditional fossil-fuel-centric operations toward chemical production and sustainable processes. With global energy landscapes shifting and climate objectives accelerating, modern refineries face increasing complexity — driving the need for advanced Process Analysis (PA), Artificial Intelligence (AI), and Machine Learning (ML) to guide this transition.

A Changing Demand Landscape

According to the International Energy Agency (IEA), global oil demand is expected to rise until 2026. However, policy changes, rapid innovation, and changing consumer behaviour could cause demand to peak earlier.

The COVID-19 pandemic intensified this shift, reshaping long-term forecasts and forcing producers to reconsider expansion plans, resource allocation, and future strategy.

Dr. Fatih Birol, Executive Director of the IEA, notes that while the pandemic caused a historic drop in demand, lasting reductions will require proactive policies and societal change. A smooth transition away from oil is essential for meeting climate targets — but it demands coordinated action.

Complexity Driving Digital Transformation

As refineries pivot from crude oil to chemicals and renewables, they face intricate challenges in process control, product variability, and supply chain management. This is where digitalization under the industry 4.0 framework becomes transformative.

Advanced PA, AI, and ML technologies reduce operational uncertainty, enhance visibility, and support optimized decision-making in real time.

Modcon.AI: Turning Data into Operational Value

Similar to how tech companies use data analytics to manage digital assets, Modcon.AI applies advanced modelling to physical and chemical process data.

Using neural networks, Modcon.AI dynamically predicts properties and compositions of process streams and recommends optimal setpoints to achieve superior performance.

These intelligent models empower operators to respond quickly to fluctuating market conditions and production challenges.

Online Crude Quality Analysis: Protecting Refining Margins

Accurate, real-time analysis of crude oil quality is crucial as refineries seek to maximize margins and optimize blends.

Process analyzers support profitability by reducing:

- production costs

- product giveaway

- unnecessary energy consumption

- labor-intensive manual sampling

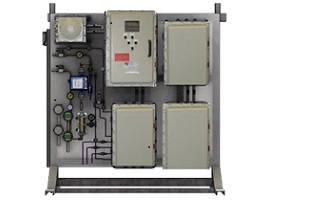

Modcon Systems’ MOD-4100 online crude analyzer plays a key role in this transformation. By measuring essential parameters — such as distillation ranges and salt concentration — it helps operators make precise blending decisions that improve operational efficiency.

AI-Driven Optimization and Reinforcement Learning

The Modcon.AI suite provides process engineers with advanced optimization tools that support connectivity, KPI prediction, and real-time validation.

Reinforcement learning (RL), particularly Deep Reinforcement Learning (DRL), enables AI agents to learn optimal operating strategies through interaction rather than historical datasets.

This makes RL especially effective for hydrocarbon processing, where dynamic environments and evolving market conditions demand adaptive, data-driven control.

Investing in a Sustainable Future

Modcon’s continued investment in PA, AI, and ML underscores a long-term commitment to sustainability. By developing advanced analytical and AI-powered solutions, the company supports refineries in achieving higher efficiency while reducing environmental impact.

As the industry moves toward cleaner technologies and chemical-focused operations, these innovations will remain vital in ensuring reliable, optimized, and sustainable refinery performance.