Enhanced Safety and Quality Control in Explosive Gas Environments

Enhanced Safety and Quality Control in Explosive Gas Environments

Handling explosive gases—such as biogas, hydrogen, and natural gas—requires strict safety and quality control. One of the most critical parameters in these gas streams is oxygen concentration. Even a slight increase in oxygen levels can raise explosion risk, reduce product quality, and initiate unwanted chemical reactions. For industries operating high-pressure pipelines, accurate oxygen measurement is not just beneficial—it is essential for safety and efficiency.

This article explores a key technological advancement transforming safety management in explosive gas environments: in-situ optical oxygen analyzers.

Why Oxygen Monitoring Matters in Explosive Gases

In gas transportation and production systems, elevated oxygen levels create two major risks:

- Explosion and fire hazards triggered by oxygen enrichment in combustible gas mixtures.

- Process integrity issues, including corrosion, bacteria growth (in biogas), and reduced product quality.

Traditional oxygen monitoring methods relied on extracting gas samples and analyzing them at reduced pressure. While widely used, this approach presents several challenges:

- Sample extraction introduces potential leak points.

- Pressure reduction alters sample characteristics.

- Conditioning systems increase complexity and cost.

- Safety risks rise when operators handle gas samples manually.

As industries move toward high-efficiency, high-pressure, and fully automated systems, these limitations have become increasingly unacceptable.

The Shift to In-Situ Oxygen Analysis

To overcome the constraints of traditional sampling, many facilities are adopting in-situ oxygen analyzers—devices installed directly in high-pressure gas lines to provide real-time oxygen readings without sampling or depressurization.

Key advantages include:

- Immediate detection of unsafe oxygen levels

- Reduced operational complexity

- No sample conditioning or venting

- Enhanced reliability and safety

Among in-situ measurement technologies, optical fluorescence-based oxygen analyzers are becoming the preferred choice.

The Power of Fluorescence Technology

Optical analyzers using fluorescence work on a non-contact measurement principle. When a special sensor dye is illuminated with a specific wavelength of light, it emits fluorescence. The decay characteristics of this fluorescence vary depending on the oxygen concentration in contact with the sensor.

Benefits of fluorescence-based analyzers include:

- High accuracy at both low and high pressures

- Exceptional long-term stability

- Minimal maintenance requirements

- Fast response times

- Simple installation and operation

Because they avoid direct contact between the gas and measurement electronics, optical analyzers are intrinsically safer for explosive gas environments.

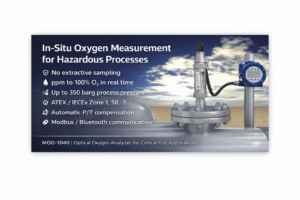

Spotlight: The MOD-1040 In-Situ Oxygen Analyzer

One of the most advanced analyzers in this category is the MOD-1040 Oxygen Analyzer, designed specifically for high-pressure, safety-critical applications.

Key Features

- Luminescence Quenching Technology: Utilizes a specialized sensor dye immobilized on a foil. When excited by red light, the dye emits luminescence captured in the near-infrared range.

- True In-Situ Measurement: Installs directly in high-pressure lines—no sample extraction or pressure reduction required.

- High Precision: Ensures stability and repeatability under challenging industrial conditions.

- Enhanced Safety: Eliminates sample handling, reducing exposure to explosive or oxygen-rich environments.

This approach is particularly valuable in hydrogen production plants, biogas upgrading systems, and natural gas distribution networks.

Benefits for Hydrogen and Other Explosive Gas Industries

Modern hydrogen production facilities rely on continuous, real-time oxygen monitoring to prevent explosive mixtures and ensure process purity. Traditional sample-based oxygen measurement increases the risk of exposure to atmospheric oxygen and often requires specialized hazardous area equipment.

In contrast, the MOD-1040:

- Provides continuous, real-time oxygen measurements

- Avoids oxygen contamination during sampling

- Reduces or eliminates hazardous area classification requirements

- Supports safer, cleaner, and more efficient operation

These advantages make in-situ fluorescence technology a major step forward in quality control and safety for explosive gas handling.

The Future of Oxygen Monitoring

As operational demands increase, industries need measurement solutions that are:

- Highly reliable

- Low maintenance

- Compatible with high-pressure systems

- Safe for explosive atmospheres

Fluorescence-based analyzers like the MOD-1040 meet these needs exceptionally well. With ongoing advancements in sensor materials and optical technology, they are poised to remain the leading solution for online oxygen analysis for years to come.