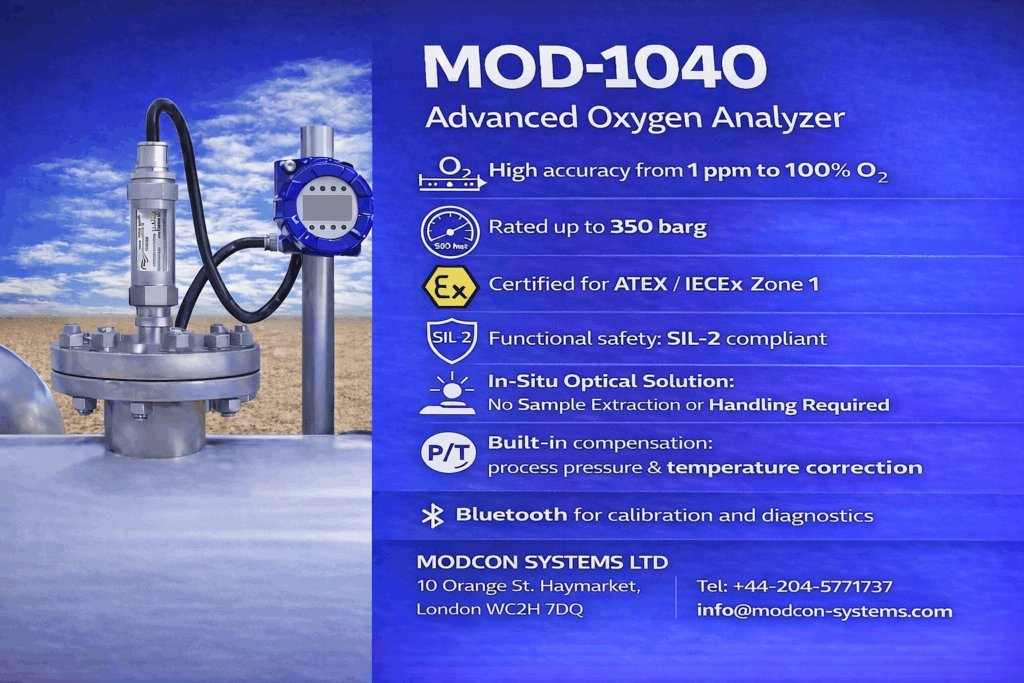

MOD-1040 In-Situ Oxygen Analyzer for High-Pressure and Hazardous Processes

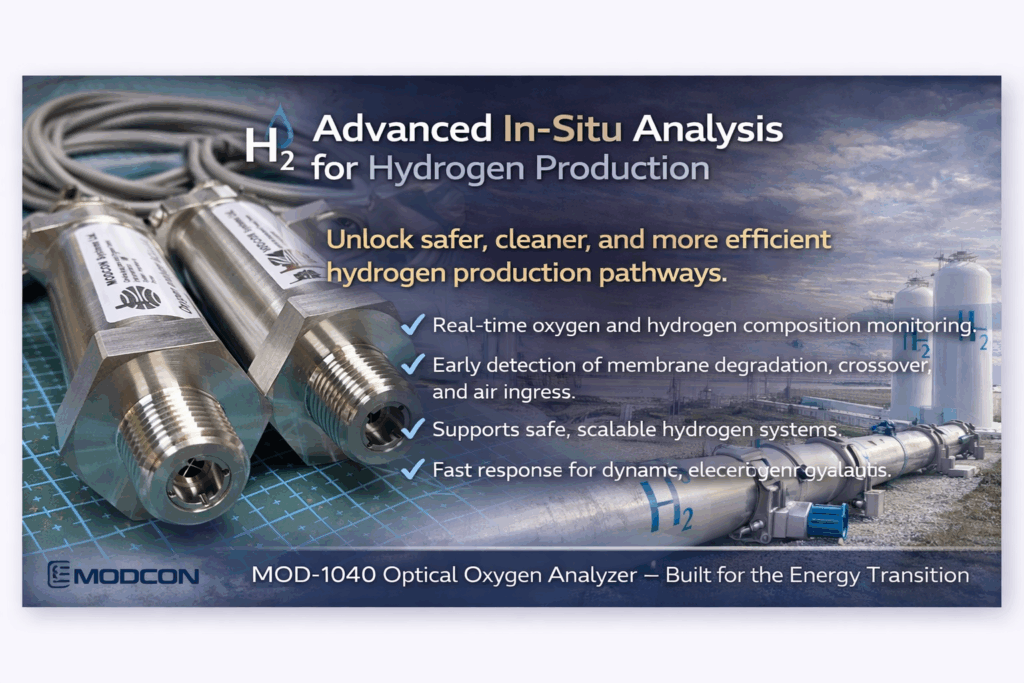

The MOD-1040 Process Oxygen Analyzer is a high-performance, in-situ measurement solution engineered for accurate and reliable oxygen analysis directly in high-pressure gas pipelines. Designed for safety-critical and mission-critical applications, the MOD-1040 eliminates the need for gas sample extraction, conditioning systems, or pressure reduction—fundamentally changing how oxygen is measured in hazardous and high-integrity process environments.

The MOD-1040 Process Oxygen Analyzer is a high-performance, in-situ measurement solution engineered for accurate and reliable oxygen analysis directly in high-pressure gas pipelines. Designed for safety-critical and mission-critical applications, the MOD-1040 eliminates the need for gas sample extraction, conditioning systems, or pressure reduction—fundamentally changing how oxygen is measured in hazardous and high-integrity process environments.

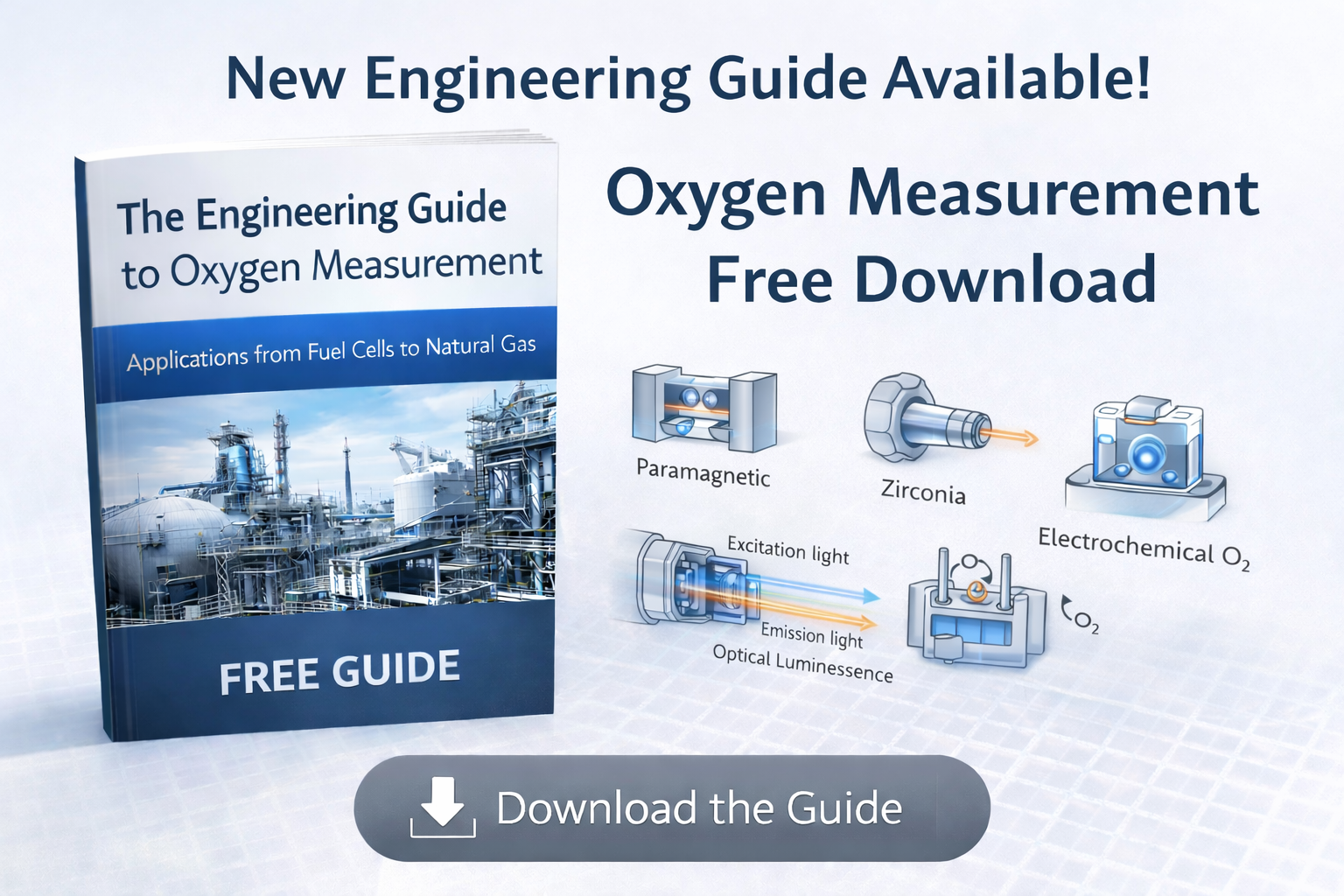

By combining advanced photonics-based sensing with rugged, explosion-proof construction, the MOD-1040 delivers precise oxygen measurements across the full concentration range—from trace ppm levels to 100% O₂—even under extreme pressure, temperature, and environmental conditions. This makes the MOD-1040 particularly well suited for hydrogen production, hydrogen compression and storage, natural gas and refinery processes, chemical production units, and industrial gas systems, where oxygen ingress represents a critical safety, quality and reliability risk.

Advanced Photonics-Based Measurement Principle

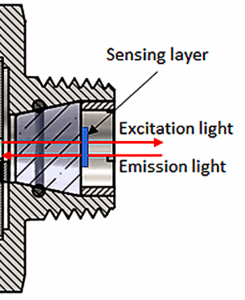

The MOD-1040 is based on advanced photonics technology utilizing luminescence quenching of a specially designed sensor dye. The sensing dye is immobilized on a robust support foil, forming a stable and highly selective sensing layer.

- The sensing layer is stimulated with red light emitted from an integrated optical source.

- The dye responds by emitting luminescence in the near-infrared (NIR) region of the electromagnetic spectrum.

- When molecular oxygen is present, it interacts with the excited dye molecules and quenches the luminescence.

- This quenching causes a reversible change in both luminescence intensity and lifetime, which is directly proportional to the oxygen concentration.

- The MOD-1040 precisely analyzes these optical changes to determine the true oxygen content in real time.

This optical principle is inherently stable, drift-free, and immune to many of the limitations associated with electrochemical, paramagnetic, zirconia or TDL-based oxygen analyzers—especially under high pressure.

Field-Replaceable Optical Sensor Architecture

The sensor technology is implemented as a compact, plug-in optical module, specifically designed for industrial field conditions:

- No electrolyte consumption

- No membrane degradation

- Easily replaceable sensor spot

- No frequent recalibration cycles

An integrated infrared light source excites the sensing layer, while the emitted near-infrared luminescence is detected and analyzed internally. The fully reversible quenching mechanism ensures long-term stability and consistent performance across a wide range of operating conditions.

True In-Situ Oxygen Measurement—Without Sample Extraction

True In-Situ Oxygen Measurement—Without Sample Extraction

Industrial gas and hydrogen production systems often operate in high-pressure, hazardous zones, where minimizing leak paths is a primary safety objective. Traditional oxygen analysis technologies are not designed to withstand such conditions and therefore rely on sample extraction, pressure reduction, and conditioning systems—introducing additional failure points, maintenance burden, and safety risks.

The MOD-1040 overcomes these limitations by enabling direct, in-situ oxygen measurement inside the process pipeline, even at very high pressures. This capability:

- Eliminates sample systems entirely

- Reduces potential leak points

- Simplifies hazardous area classification

- Lowers installation and lifecycle costs

- Improves measurement response time and reliability

As a result, MOD-1040 allows engineers to confidently deploy oxygen measurement even in locations previously considered impractical or unsafe.

Engineered for Hydrogen and Safety-Critical Applications

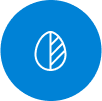

In green and blue hydrogen production, oxygen contamination can lead to:

- Increased explosion risk

- Catalyst degradation

- Reduced product purity

- Accelerated material aging

The MOD-1040 is specifically engineered to address these challenges. Its optical sensing technology is ideally suited for hydrogen service, offering fast response, high selectivity, and intrinsic safety, even under pressures reaching hundreds of bar.

Automatic pressure and temperature compensation ensures that the reported oxygen concentration reflects true process conditions, not measurement artifacts caused by fluctuating operating parameters.

Key Capabilities and Technical Specifications

Measurement Performance

- In-situ oxygen measurement range: 1 ppm to 100% O₂

- Response time (T90): < 5 seconds

- Automatic pressure and temperature compensation

Operating Conditions

- Maximum operating pressure: up to 350 barg

- Ambient temperature range: –10 to +60 °C

- Designed for continuous operation in harsh industrial environments

Safety and Compliance

- Explosion-proof certification: II 2 G Ex db IIC T4 Gb

- SIL-2 certified in accordance with IEC 61508-2:2010

- Suitable for ATEX / IECEx Zone 1 installations

Integration and Connectivity

- Modbus communication for DCS, PLC and HMI systems

- Bluetooth interface for commissioning, diagnostics and maintenance

- Industrial-standard 4–20 mA analog inputs and outputs, enabling seamless integration with pressure and temperature transmitters and direct communication with DCS, PLC and safety shutdown systems.

- Compact, rugged design for direct pipe mounting

A New Standard for Oxygen Analysis in High-Pressure Processes

The MOD-1040 Process Oxygen Analyzer is not simply another analyzer option—it represents a step change in how oxygen is measured in high-pressure and hazardous environments. By combining photonics-based luminescence quenching, in-situ installation, and uncompromising safety certifications, the MOD-1040 enables safer plant designs, higher measurement integrity, and lower total cost of ownership.

For hydrogen production, refinery operations, and advanced industrial gas systems, the MOD-1040 sets a new benchmark for precision, safety, and operational efficiency.

Contact us to learn how the MOD-1040 can be integrated into your process architecture and safety strategy.

Contact us to learn how the MOD-1040 can be integrated into your process architecture and safety strategy.