As global efforts to decarbonize intensify, renewable fuels are becoming a cornerstone of the transition toward cleaner, more sustainable energy. Yet, moving from traditional hydrocarbons to renewables is far from simple.

Feed variability, catalyst performance, and fluctuating ambient conditions all demand continuous adaptation and process optimization to maintain efficiency and profitability.

The Challenge of Renewable Fuel Production

While renewable fuels promise reduced emissions and environmental impact, their production processes are dynamic and complex. Feedstocks such as bio-oils and waste-derived materials vary widely in composition and quality, requiring refineries to constantly adjust temperature, pressure, and catalyst activity to achieve consistent yields.

Whether co-processing renewable feeds with conventional hydrocarbons or operating fully renewable units, the underlying challenge remains the same—how to maintain efficiency and maximize value amid constant change.

Smart Optimization: The Role of Advanced Hardware and Software

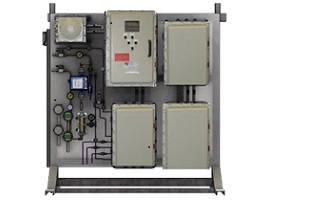

To address these challenges, refiners are increasingly turning to integrated systems of on-line process analyzers and optimization software. By combining real-time analytical data with economic parameters, operators can perform closed-loop optimization of blending and processing operations.

Technologies such as Beacon-3000, MOD-4100, and Modcon.AI are at the forefront of this transformation. Together, they provide a comprehensive toolkit for monitoring, predicting, and optimizing process performance based on live plant data.

Artificial Intelligence and Predictive Modeling

At the heart of this digital transformation lies Modcon.AI, which employs advanced artificial neural network (ANN) models to simulate and predict the physical and chemical properties of process streams. These predictive models enable operators to:

- Accurately forecast process behavior

- Adjust operating parameters in real time

- Improve yield, quality, and energy efficiency

By using these insights, refineries can make smarter, faster decisions and ensure that renewable fuels production remains both efficient and profitable.

Reinforcement Learning for Continuous Improvement

Beyond neural networks, Deep Reinforcement Learning (DRL) is reshaping how industrial processes are optimized. Unlike traditional algorithms that depend heavily on historical data, DRL systems learn dynamically through trial and feedback, refining their strategy to maximize performance and profit.

In the context of hydrocarbon and renewable fuel processing, DRL agents can optimize complex operations—such as temperature control, blending ratios, and throughput—based on real-time feedback from process analyzers.

Real-Time Monitoring: The Foundation of Optimization

Real-time on-line analyzers play a pivotal role in validating predictions and guiding process control. By continuously measuring the chemical composition and physical properties of process streams, they provide the data backbone required for reliable optimization and digital twin modeling.

This integration of analyzers and AI-driven models allows refineries to fine-tune their operations, minimize waste, and improve both yield and environmental performance.

Defining Key Performance Indicators (KPIs)

Effective optimization begins with clear, measurable Key Performance Indicators (KPIs). For downstream industries, these often include parameters tied to product quality—like viscosity, sulfur content, and energy output—as well as safety and environmental compliance metrics.

By aligning these KPIs with linear programming models, refineries can establish optimization frameworks that balance profitability with sustainability goals.

Toward a Smarter, Greener Refinery

Dynamic process optimization, supported by real-time analytics and AI-driven modeling, represents a powerful path forward for renewable fuel producers. Refineries that embrace these technologies can reduce costs, improve efficiency, and make measurable contributions to a low-carbon future.