Modcon Systems announces its latest Modcon-AI HW/SW crude blending package

a sophisticated solution designed to optimize crude blending in modern refineries and blending services operations. By combining real-time analytics with deep learning process control and digital twin modeling, this system empowers operators to improve margins, reduce risk, and respond dynamically to market conditions.

The Challenge: Margin Pressure & Feedstock Complexity

Refinery profitability hinges on effective crude feedstock strategies. Since as much as 80–90% of refinery operational cost is tied to crude purchase, minimizing feedstock cost without sacrificing product output is critical.

Today’s refining landscape demands flexibility. Refineries increasingly blend expensive light crude with cheaper unconventional or heavy crudes to produce synthetic crude that meets processing constraints and yields high-value distillates.

Key blending challenges include:

- Varying quality characteristics — such as density, total acid number (TAN), sulfur content, and distillation behavior

- Risk of asphaltene precipitation when blending incompatible crudes, leading to fouling and operational issues

- The need to respond dynamically to changing market demands (for example, shifts from gasoline to diesel consumption)

Inline Blending & Analytics: A Modern Approach

Traditional tank blending involves mixing crudes in storage and adjusting blend ratios over time. In contrast, in-line blending merges different crude streams through a static mixer into a final blend, allowing real-time adjustments by altering feed ratios.

To prevent problems like asphaltene precipitation when combining heavy or polar crudes, continuous monitoring is crucial. Modcon’s approach integrates online analyzers, measuring critical properties (e.g. SARA composition) to guide blending decisions without needing to rely solely on predictions.

The Modcon-AI Blending Package

At the heart of the system is a digital twin, driven by deep reinforcement learning (DRL). This model simulates the process behavior under various blend configurations, predicting physical and chemical properties of stream compositions and suggesting optimal setpoints.

A key feature: the model does not require historical data to begin operation. However, DRL tends to perform best when starting parameters are already reasonably close to optimal. That’s why continuous integration of real-time analytics is essential — enabling the system to refine predictions and maximize accuracy over time.

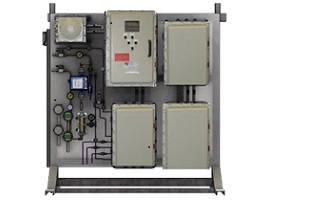

Complementing the software, the MOD-4100 on line crude oil analyzer provides in-situ measurements of multiple parameters correlated to ASTM standards, including:

- Salt concentration

- Distillation curves

- SARA fractions

- Emulsion stability

- Hydrogen sulfide content

- RVP (Reid vapor pressure)

- Viscosity

- Water content

- Sulfur content

- Density

This single analyzer supports modular on-site installation and real-time feedback to the blending system.

Benefits & Use Cases

By marrying real-time analysis with advanced modeling, Modcon’s solution allows:

- Dynamic adjustment of blend ratios during production

- Faster response to feedstock or market fluctuations

- Reduced operational risk by monitoring compatibility and preventing precipitation

- Enhanced profitability through better margin management

The system can be deployed either by traders offering blending services or by refineries operating their own blending stations. In both scenarios, it supports higher margin capture and more agile operations.

Conclusion

Modcon’s advanced crude blending solution represents a strategic leap forward in refinery operations. By embedding real-time analysis and predictive modeling, oil processors can better navigate the complexity of modern feedstocks, optimize blending performance, and enhance profitability in today’s volatile energy environment.